【ベストコレクション】 s&op demand planning process 863495-S&op demand planning process

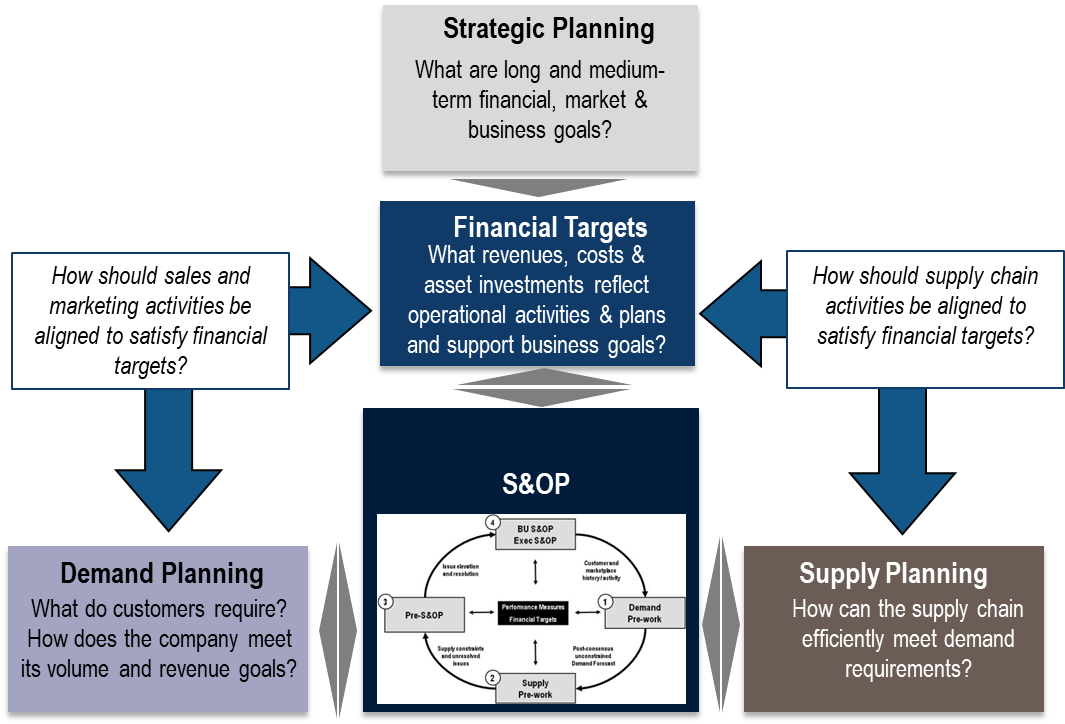

An effective S&OP strategy is one that ensures one version of truth based on the demand plan or the agreed consensus forecast In reality, however, any organisation is likely to have multiple planning numbers, such as revenue targets, finance budgets and manufacturing targets A mature planning processIn order for the demand plan to capture the information that all consumers of the S&OP will need, those responsible for creating the demand plan would do well to address several key questions These questions help participants define what exactly is being forecast and how the demand plan should be structured What Is Sales and Operations Planning (S&OP)?

1

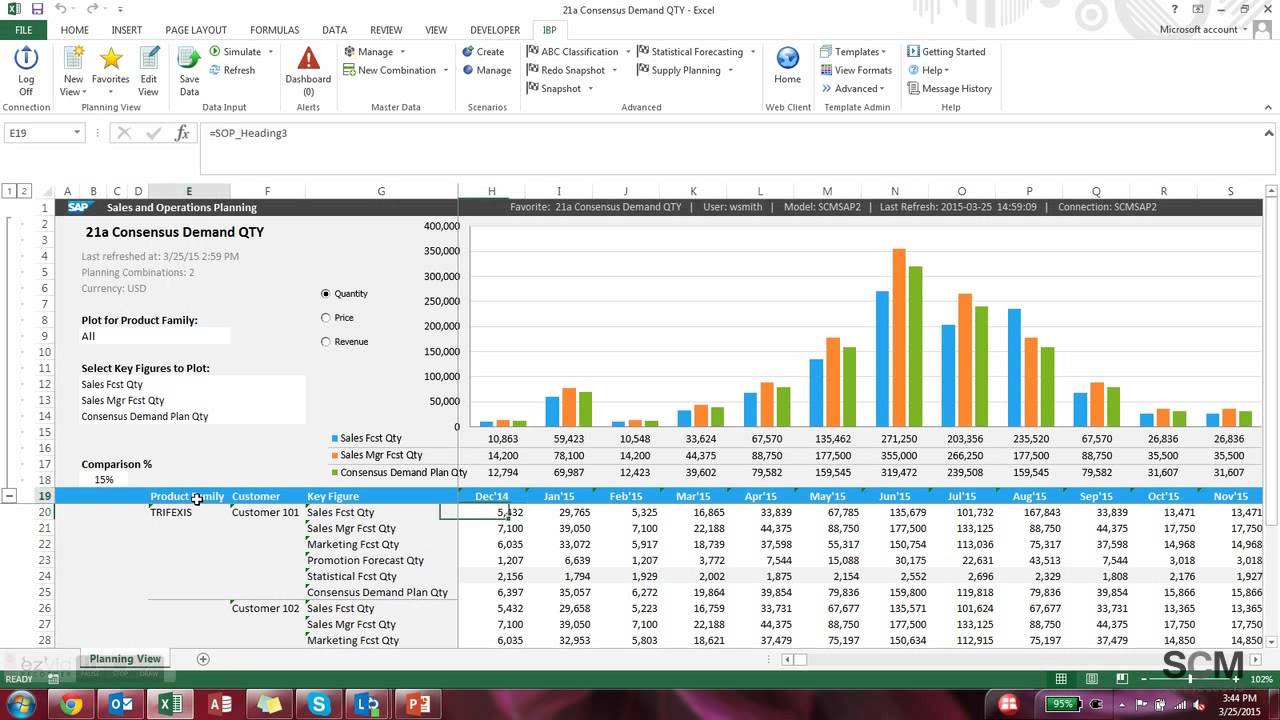

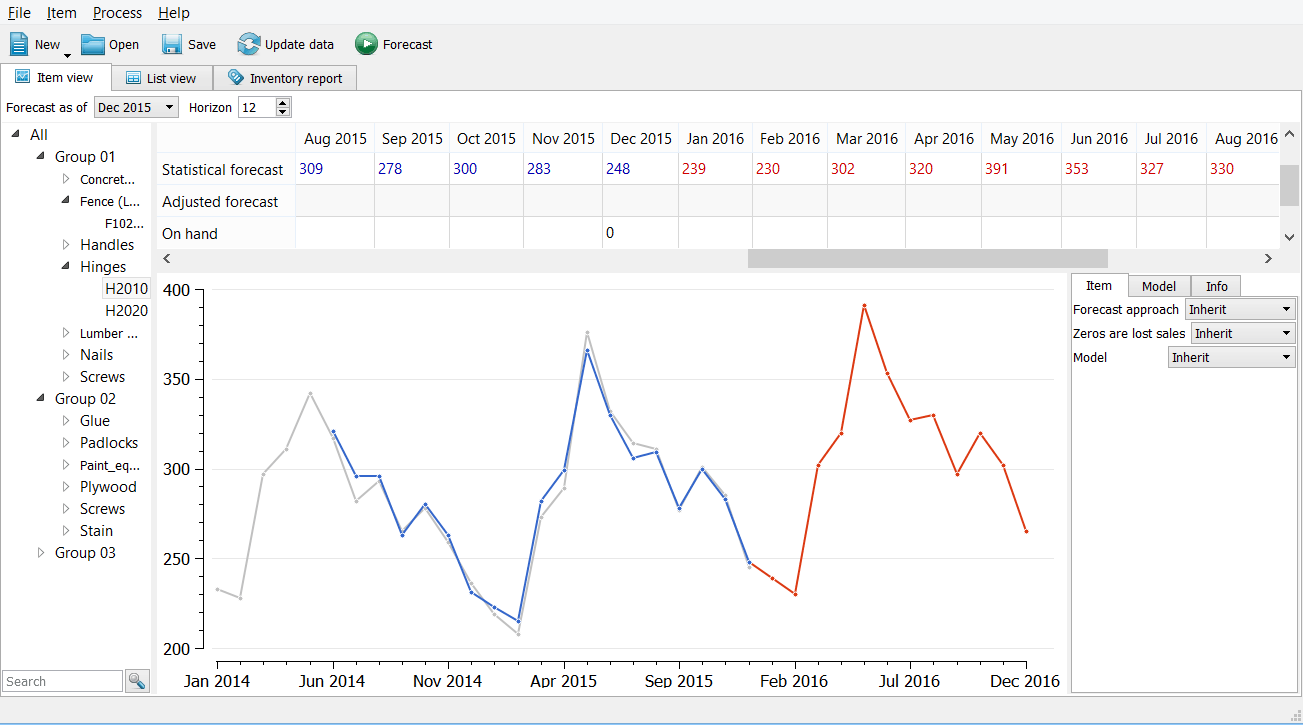

S&op demand planning process

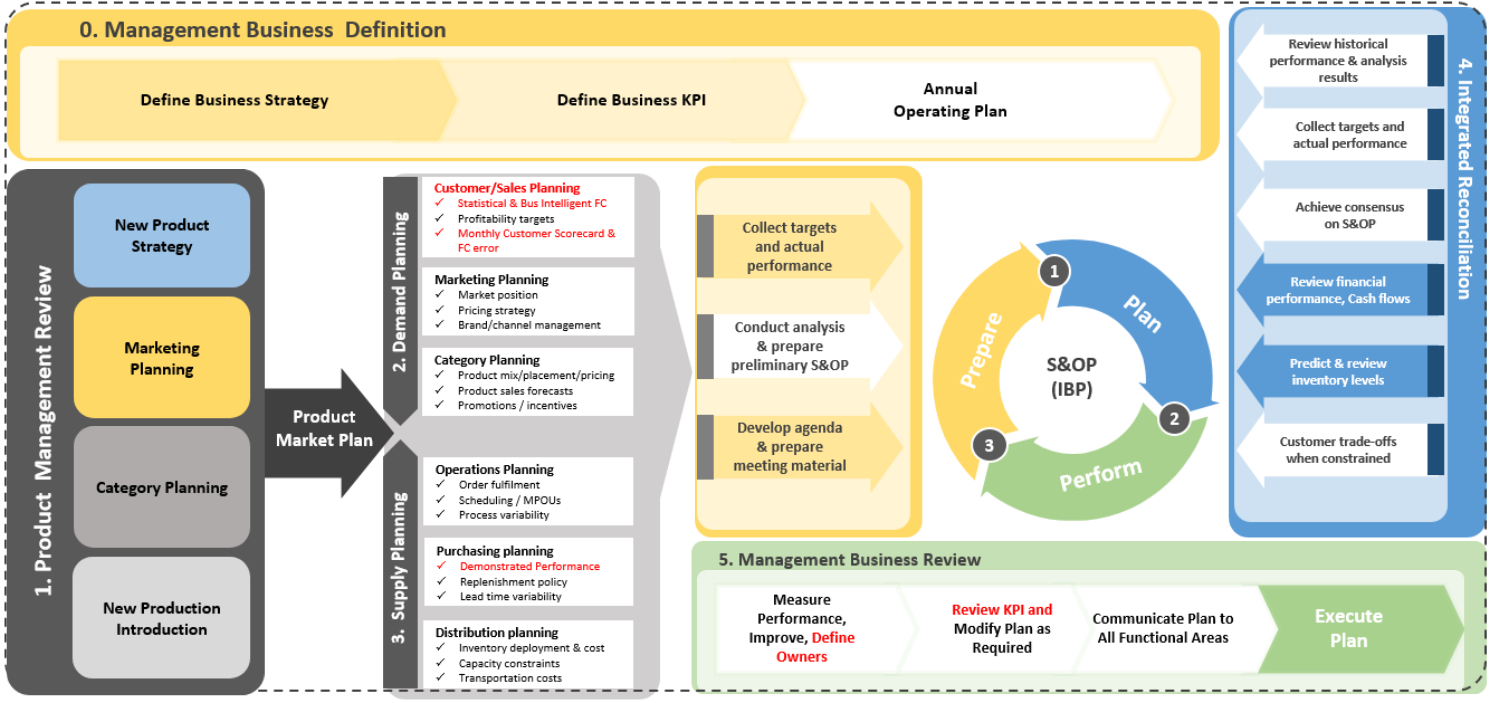

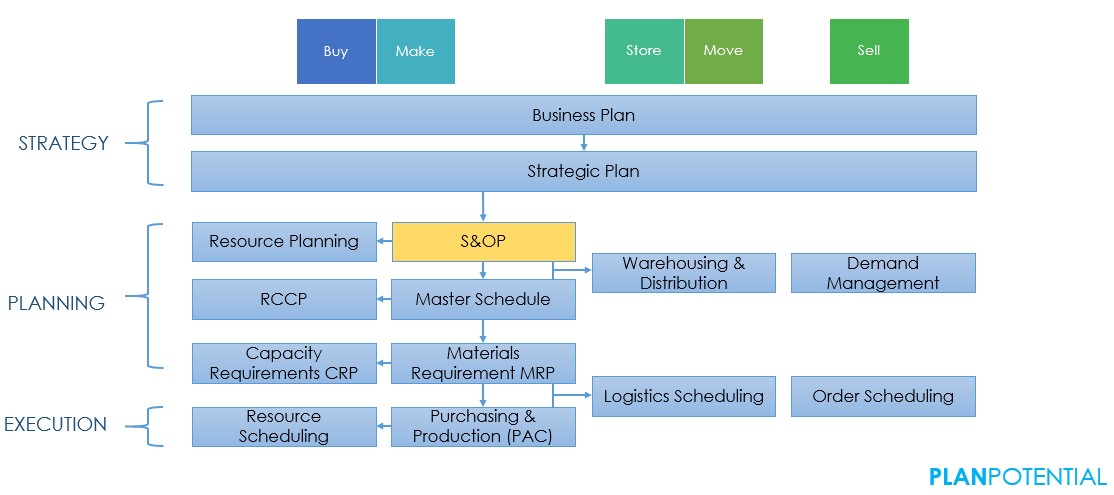

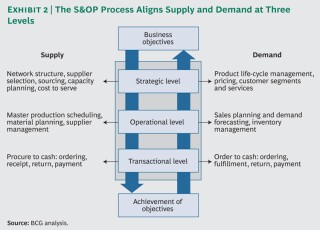

S&op demand planning process-The Institute of Business Forecasting defines S&OP as "a process that integrates demand, supply, and financial planning into one game plan for business It also links strategic plans to operational plans, and attempts to develop the most desirable product portfolio and product mix to maximize sales and profit"S&OP journey on tools Partially in SAP Manual Excel SAP ECC & SCM 40 Live SAP ECC (60) & SCM (70) upgrade Future –create process efficiency 06 08 10 12 14 16 SAP project launch Fully in SAP 5 S&OP enablers SAP Journey New future technologies –S&OP on

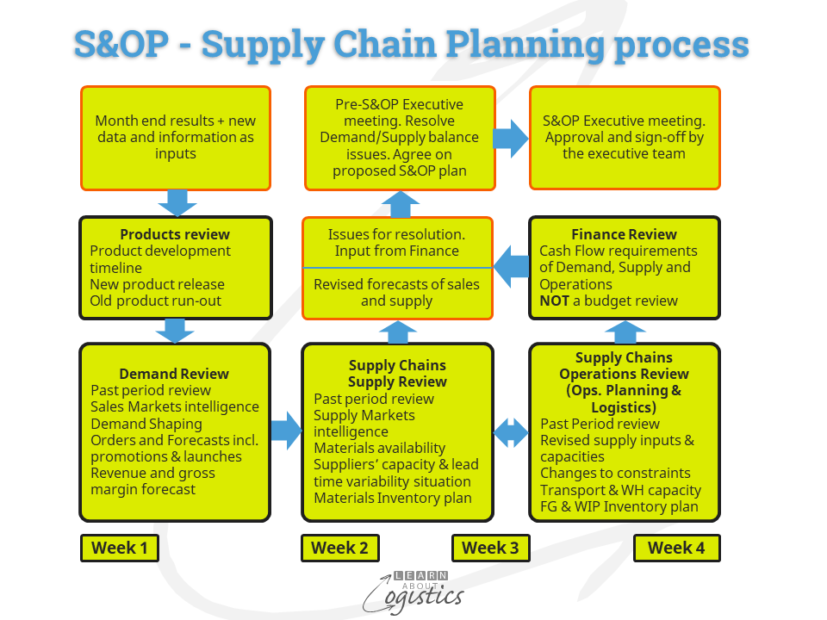

What Is S Op Or Sales Operation Planning Sales And Operation Planning Definition And Steps

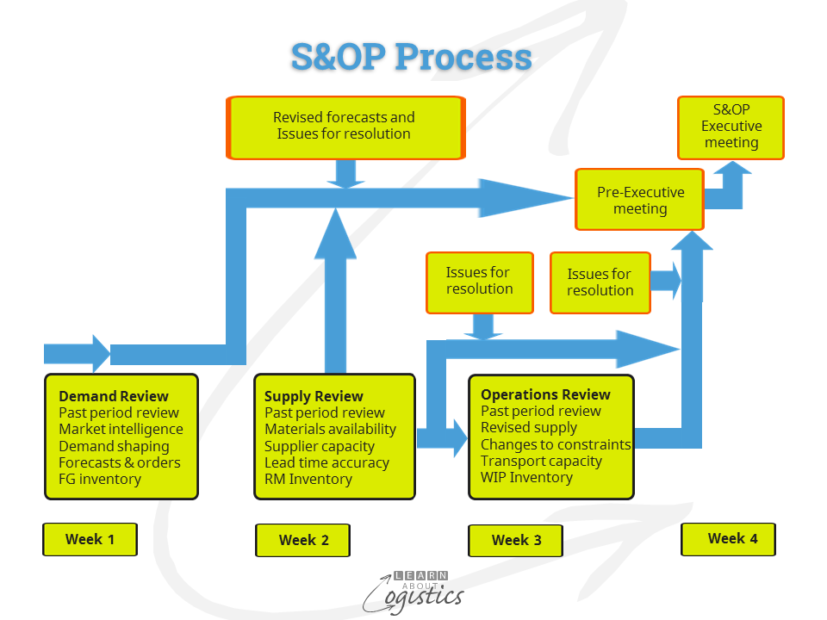

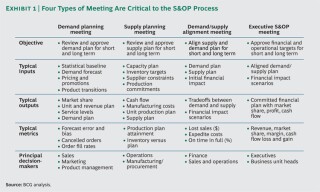

While approaches vary among industries and companies, they typically focus on a monthly S&OP planning process with a longterm planning horizon ranging from 18 to 36 months The annual overall business plan ties in with all other The demand consensus meeting is one of the most important steps in sales and operations planning (S&OP), with the resultant demand plan serving as a critical input for all other S&OP process meetings Without a demand plan as aAs a natural progression, CPG companies started adopting S&OP process to develop forecast consensus and holistic planning Most CPG supply chains have an active Sales and Operations Planning Process, which is crossfunctional with participation from Sales, Marketing, Logistics, Supply Planning, Finance, Sales Planning and Demand Planning functions

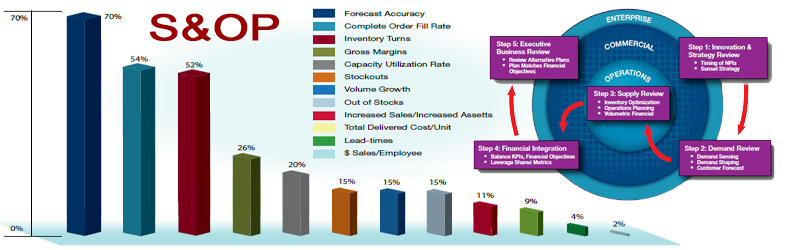

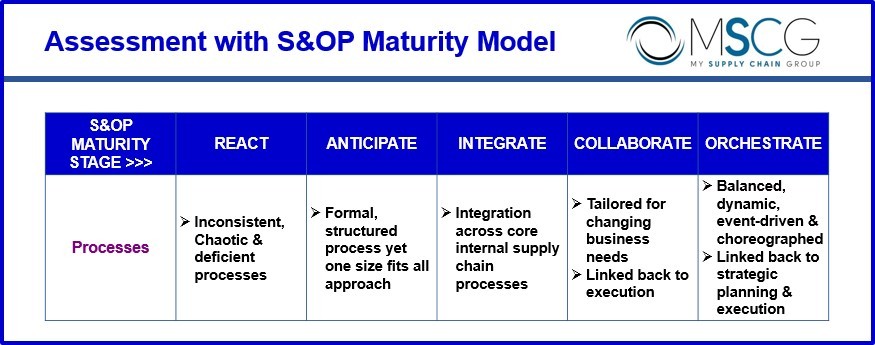

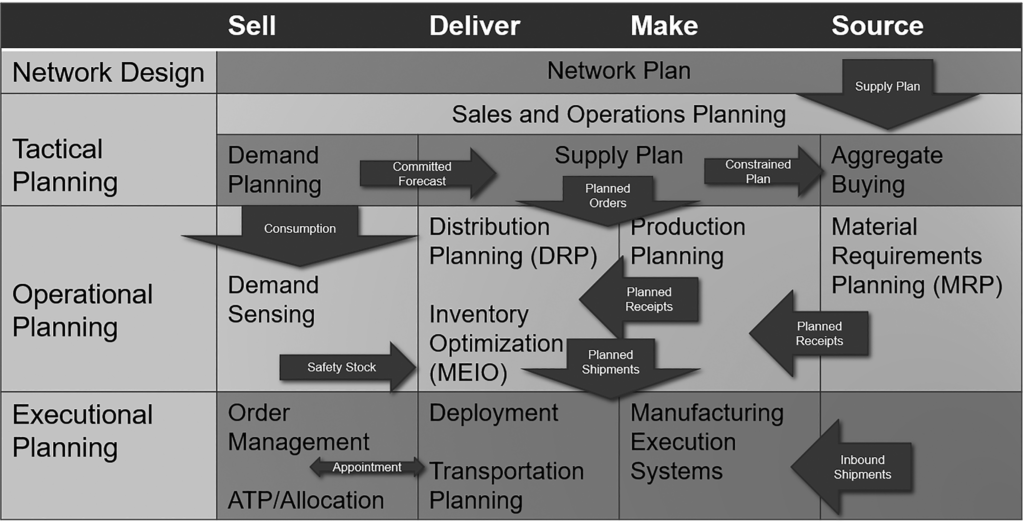

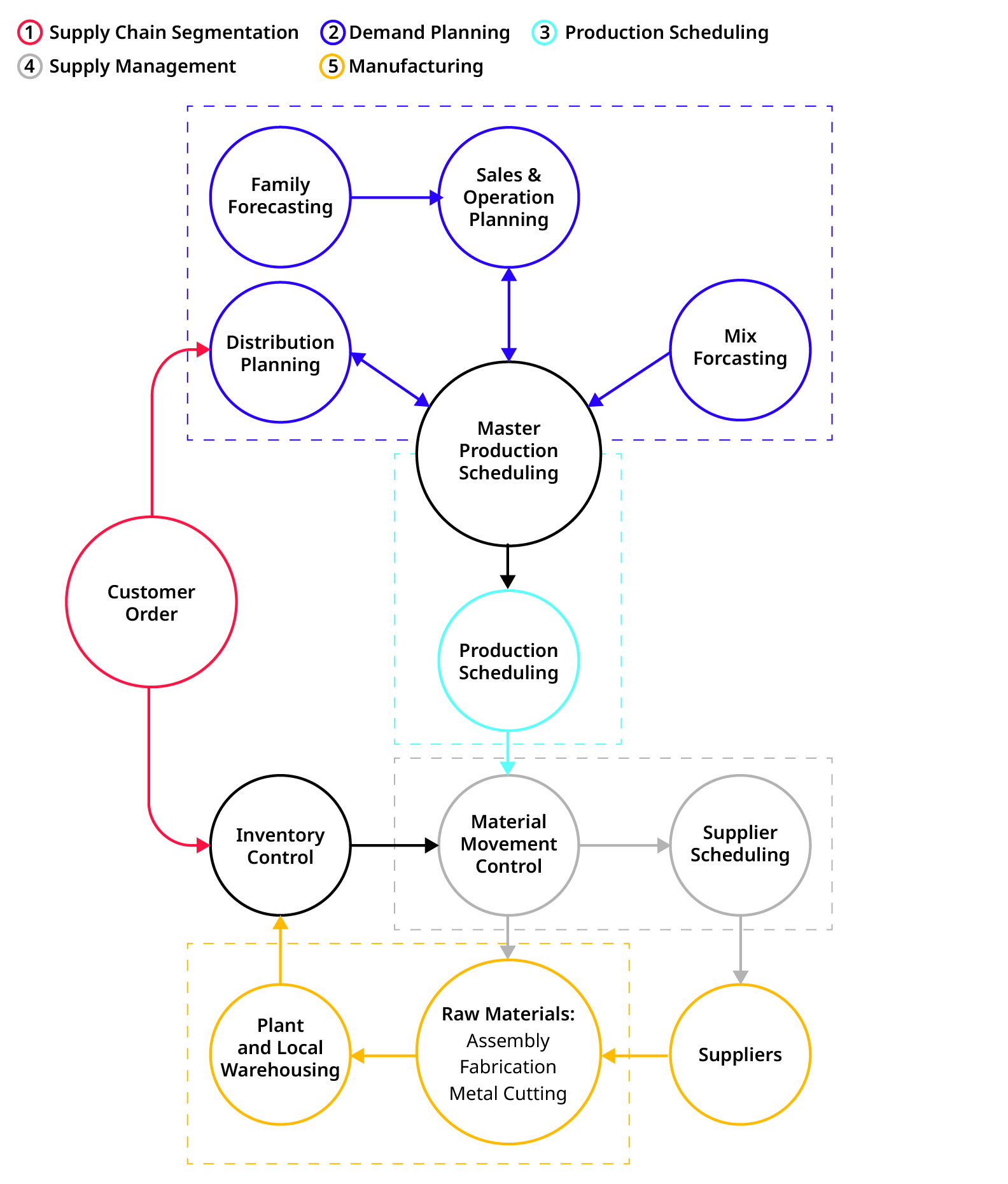

Demand planning is a supply chain management process of forecasting, or predicting, the demand for products to make sure that they will be delivered and satisfy customers The goal is to strike a balance between having sufficient inventory levels to satisfy customer needs without having a surplusS&OP ConsultingProcess Design and Reengineering Sales and Operations Planning Process thrives on collaboration and honest communication between key organizational players Our process design approach is driven by the understanding of key touch points in the organization and how effective demand and supply communication among these touchAs a collaborative process that balances supply and demand, the benefits of S&OP include Higher profitability The S&OP process helps maintain a cohesive, balanced plan It drives great customer service, Better decisionmaking With S&OP software

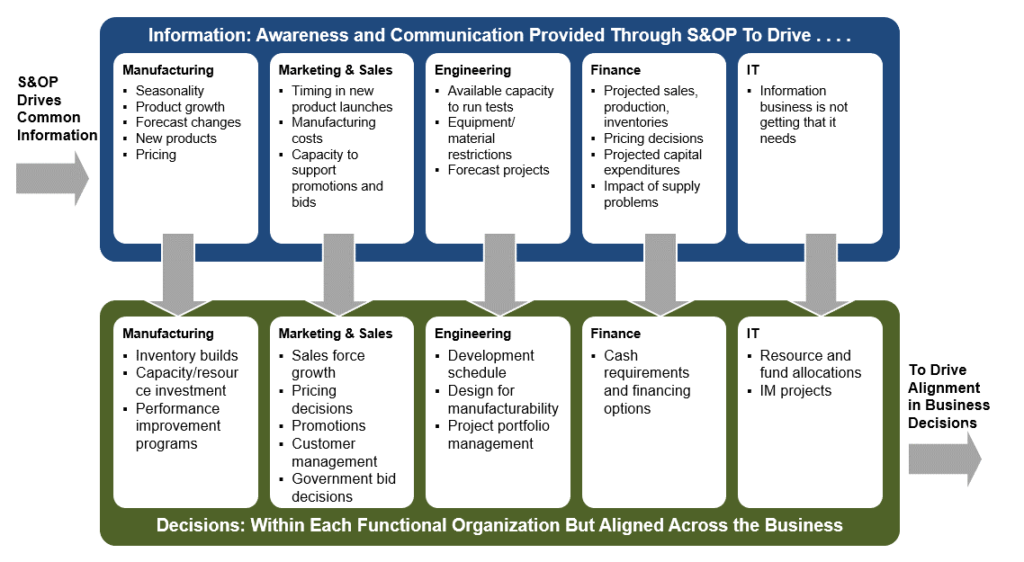

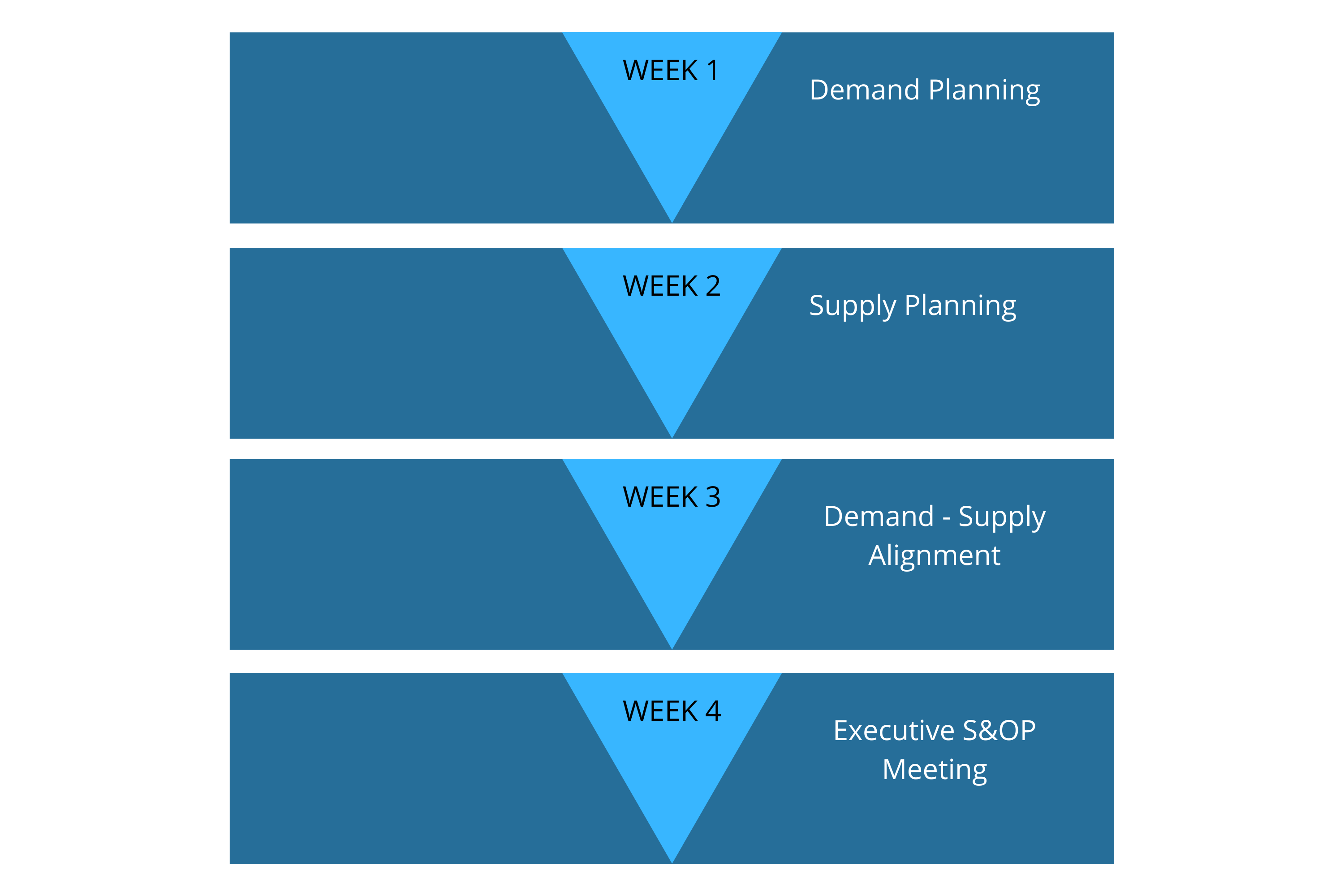

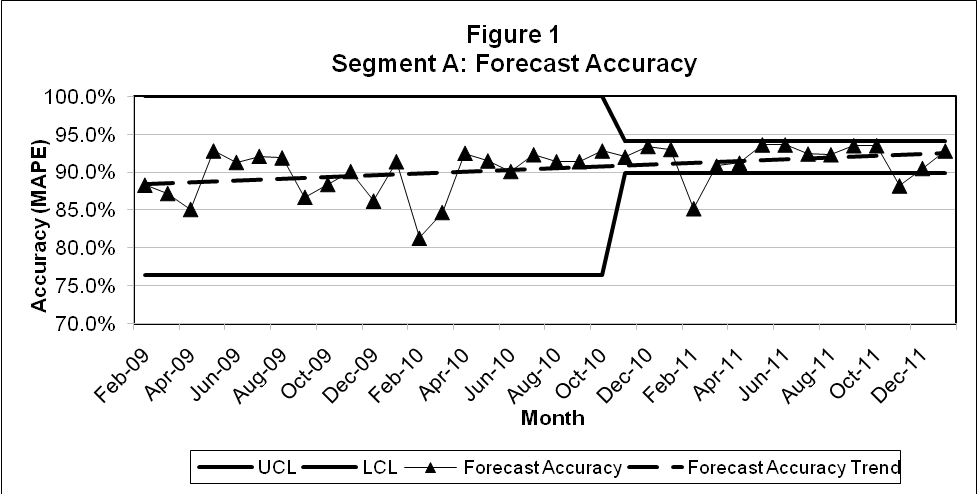

The demand planner's role in the S&OP process typically places him/her in the Operations Department Therefore, they frequently serve as a link between a company's Sales and Marketing Organization and their Manufacturing Organization Demand Planning has the first six workdays of the monthly S&OP process to report KPIs, revise baseline and/or event forecasts, and review results with key internal partners Demand Planning finalizes the demand plan, and hands it over to Supply Planning on day sevenWhat is Sales & Operations Planning (S&OP)?

Demand Supply Planning Process In The Examined Demand Supply Network Download Scientific Diagram

Ready To Upgrade Your S Op Process For Industry 4 0

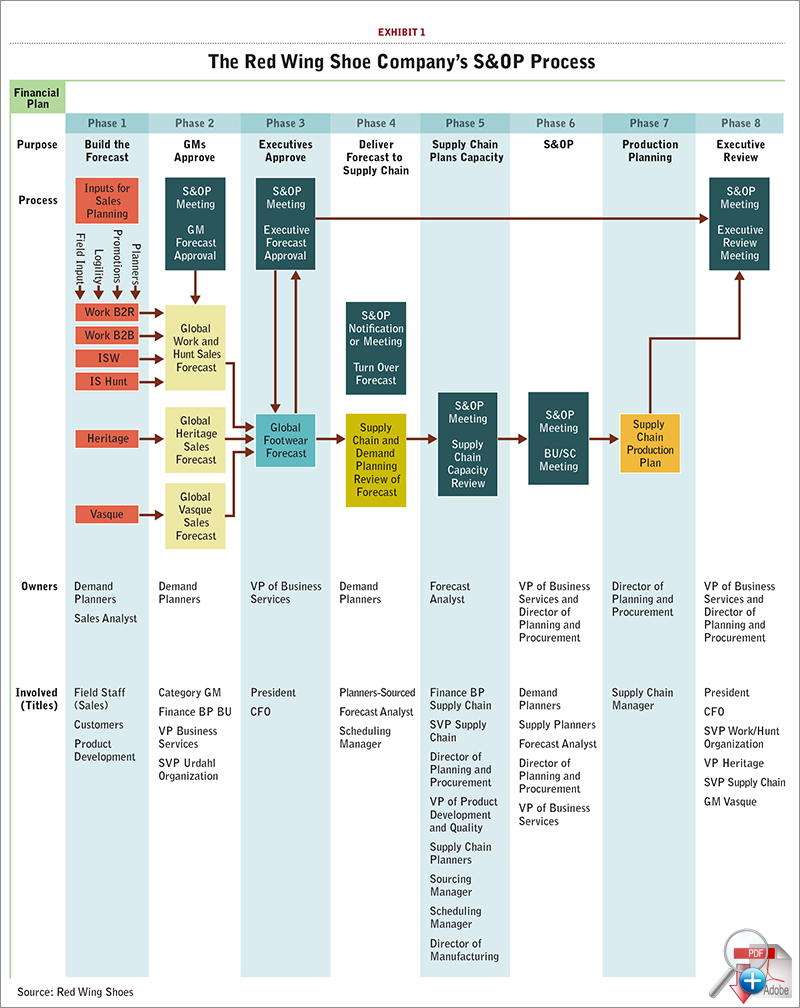

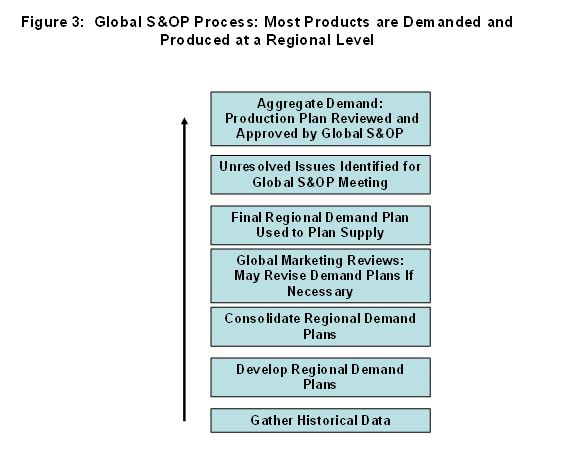

The overall objective of the Global S&OP process is to maximize operating results within the service level and inventory constraints Highlights of the process include the following Demand planning is performed on a regional basis as regional marketing and sales are closest to their market and are held accountable for meeting the sales plan Plex DemandCaster Supply Chain Planning Knowledge Base S&OP Legacy Application Net Demand Planning (POS Integration) Net Demand Planning Process Net Demand Planning Process This is an optional feature that is helpful to any company that is tasked with managing customer inventories and/or has access to their customers sales or consumption data The Institute of Business Forecasting & Planning (IBF)est 19, is a membership organization recognized worldwide for fostering the growth of Demand Planning, Forecasting, and Sales & Operations Planning (S&OP), and the careers of those in the field

Sales And Operations Planning Explorescm

S Op Software Sales And Operations Planning Qad Dynasys

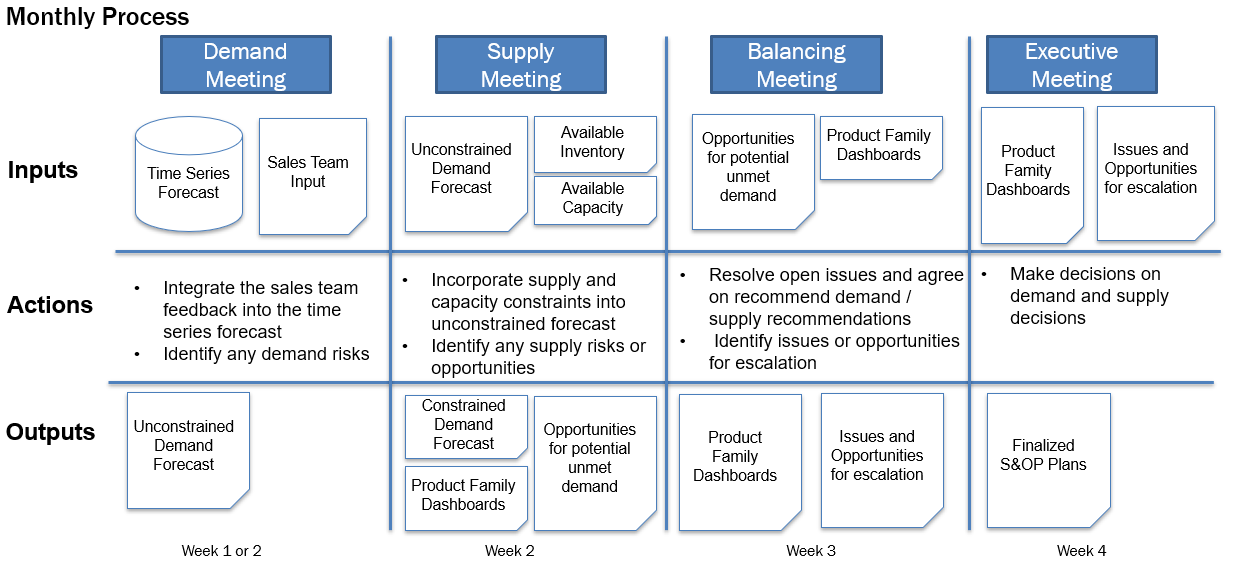

What is Sales and Operations Planning (S&OP) and why do you need it?At a recent seminar Steven Thacker explained 👇 TIMESTAMPS (in case you want to skip) 👇The Sales and Operations Planning Process (S&OP) is best defined as a planning process to ensure the business maintains sufficient inventory to meet customer demand The S&OP process typically operates on a monthly cadence, and includes a series of meetings that drive alignment between sales, marketing, and supply chainS&OP Meetings An S&OP Process Is Driven by a Baseline Demand Forecast • Unconstrained Demand Forecast • Constrained Demand Forecast • Supply Plans •Rough Cut Supply Plans •Supply Constraints Demand Supply •Baseline Demand Forecast • Must be estimate of true unconstrained demand • The "Sanity" check • Must represent unbiased, unemotional view

Sales And Operations Planning S Op Is All About Balancing Supply And Demand Implement Consulting Group

Gartner Blog Network

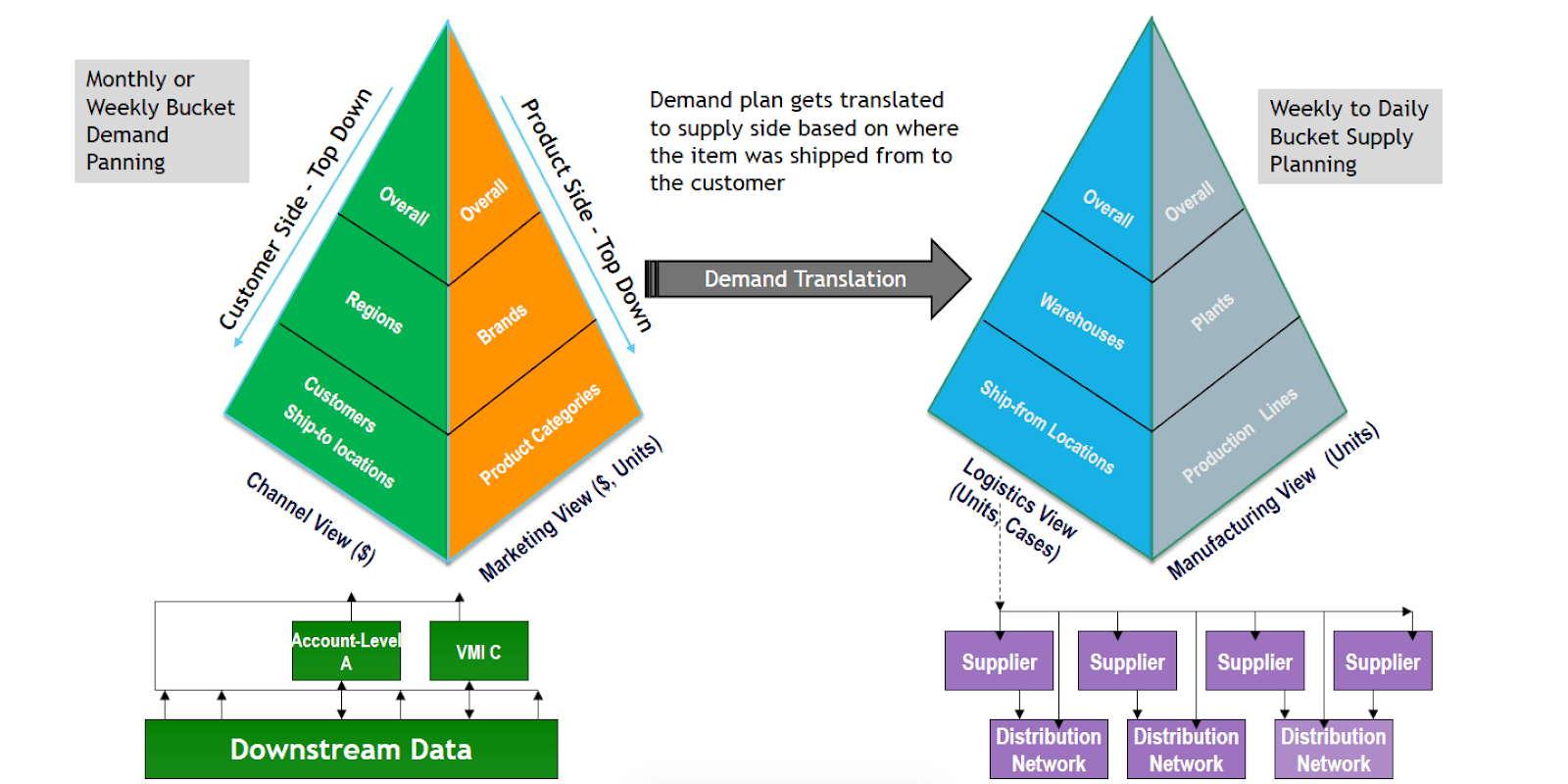

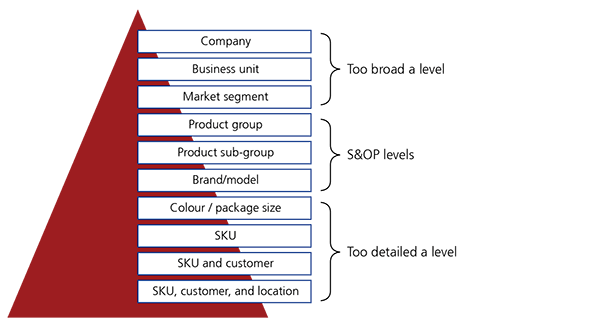

The sales and operations planning process enable the company to effectively manage the demand of its customers It holds the capacity of its operations too Sales and operations planning generates a uniform and agreedto set of numbers used to drive the business S&OP – Planning Worksheet 66 S&OP – Information Flow S&OP Spreadsheet Demand Information Supply Information Summarised by family, sub family, by month, In lbs Order fill % Shortages KPI Actuals Prod Pln KPI Forecasts Actuals Util % OT Inventory Ad Each month or planning period, the S&OP demand and supply planning process follows a very specific linear work flow as outlined in this article Setting a planning hierarchy is a critical part of generating appropriate forecasts The demand planning hierarchy is top down one to many within the sales level and also within the product level

1

Sap Integrated Business Planning Ibp Sales And Operations Planning 18 Sap Blogs

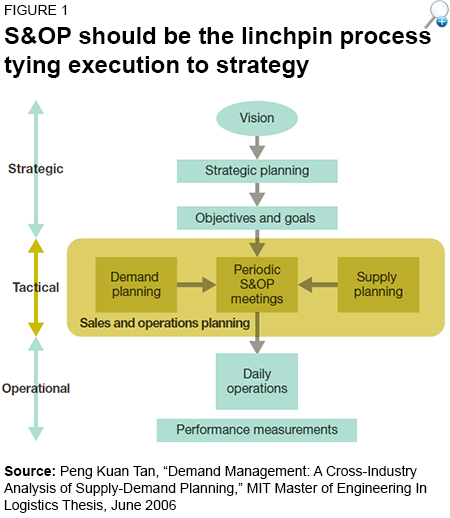

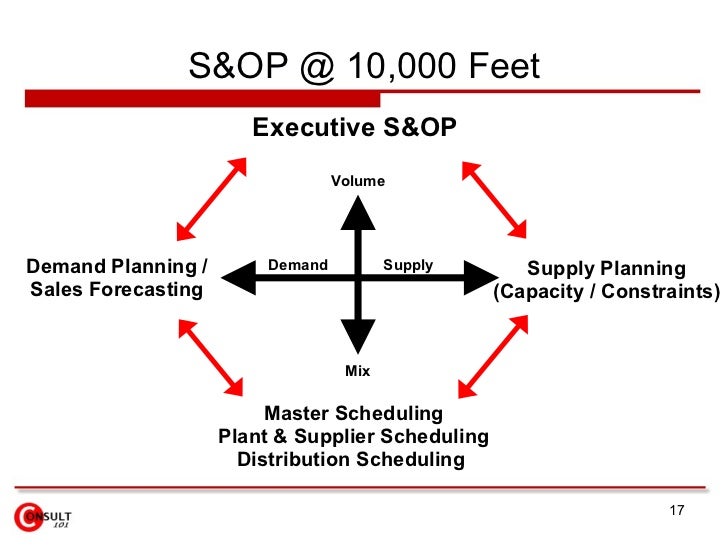

S&OP process In order to balance sound business decisions to construct the best overall plan, the S&OP team must have accurate, reliable information – the current status, future conditions, constraints, and concerns about demand, production, inventory, procurement, and finance They must also know how changes and decisions in one area impactExecutive S&OP is a decisionmaking process that balances demand and supply at the aggregate level, aligns operational planning with financial planning, links strategic planning with daytoday sales and operational activities, and sets the tactical direction of the businessSales and operations planning (S&OP) is an integrated planning process that aligns demand, supply, and financial planning and is managed as part of a company's master planning S&OP is designed and executed to support executive decisionmaking related to approving a feasible and profitable material and financial plan

What Are The Basic Elements Of The S Op Process Quora

What Is S Op Or Sales Operation Planning Sales And Operation Planning Definition And Steps

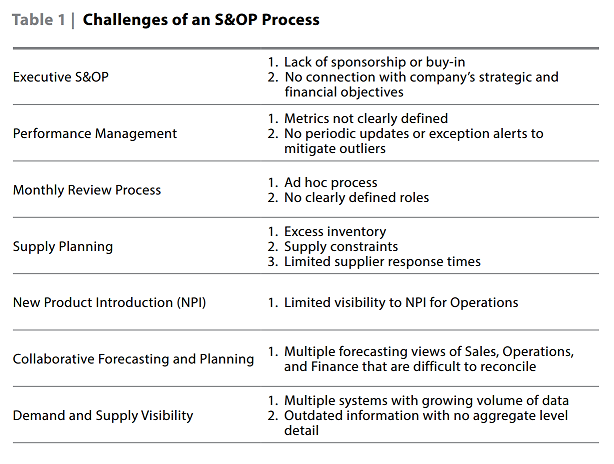

Demand Forecasting Automatic Replenishment & Allocation Inventory Planning & Optimization Sales and Operations Planning (S&OP) Production Planning & scheduling Promotions planning Want to learn more about SUPPLY CHAIN PLANNING?Sales and operations planning has evolved into a major business process adopted to manage the balance and tradeoff between the conflicting preferences of the supply and demand side of the supply chain and offers many value creation opportunitiesThe Key steps in an S&OP process redesign Assess the key objectives of the Planning Process Identify and Involve stakeholders in Sales, Supply Planning, Operations, Marketing, and Finance during the process definition phase Interview key General Managers and understand their informational needs from the Sales and Operations Planning process Identify the key pain points

What Is One Plan S Op Arkieva

Top Performer Benefits Of Effective Sales Operations Planning Supply Chain 24 7

Defining the S&OP Process How do you define S&OP at your organization?S&OP process, one "needs a process that is able to chase demand or supply quickly" Most S&OP processes in place today tend to fail in this regard The major issue is that they tend to presume a given set of marketing and sales plans In these cases, the S&OP process primarily entails developing supply plans that meet the demandHttp//demandplanningcom//usingexceltopresentupdateforecastsatthedemandreview/ S&OP is a structured monthly process that aligns all functional areas under a unified set of assumptions to enable and coordinate decision making

Road Map Of Integrated Business Planning For Supply Chain Part Ii The 5 Ps Of S Op Maturity My Supply Chain Group

Achieve Excellence In Sales And Operations Planning Sapinsider

S&OP, or sales & operations planning, is a monthly integrated business management process that empowers leadership to focus on key supply chain drivers, including sales, marketing, demand management, production, inventory management, and new product introduction With an eye on financial and business impact, the goal of S&OP software is to enable executives to make better S&OP deals with the continuous change that occurs in the business and is a process to effectively manage ongoing change In practice, it is called a replanning process S&OP is owned by the GM or CEO It is a crossfunctional process and includes all the functions of the company Correctly implemented, it is a demand and strategydriven processPlex DemandCaster Supply Chain Planning Knowledge Base S&OP Legacy Application S&OP Platform Overview and Setup Legacy S&OP Pareto Process S&OP Pareto Process The Pareto is a method of focusing the demand planning process on

S Op Sales And Operations Planning And Sco

Sales Operations Planning Consulting Supply Velocity

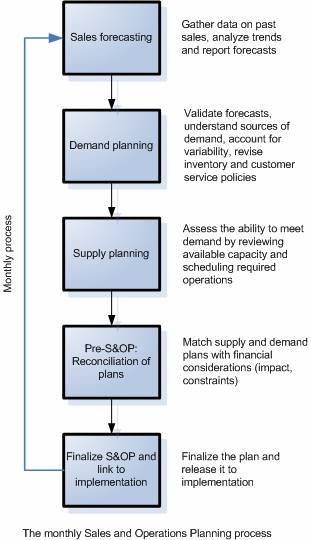

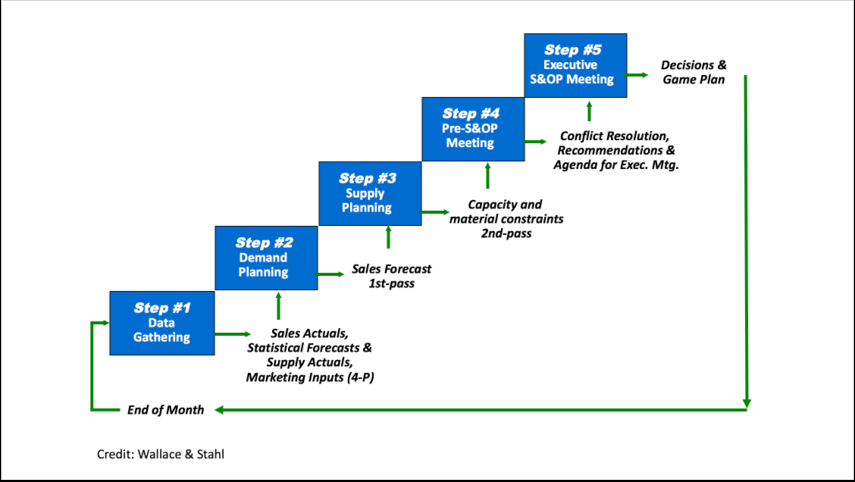

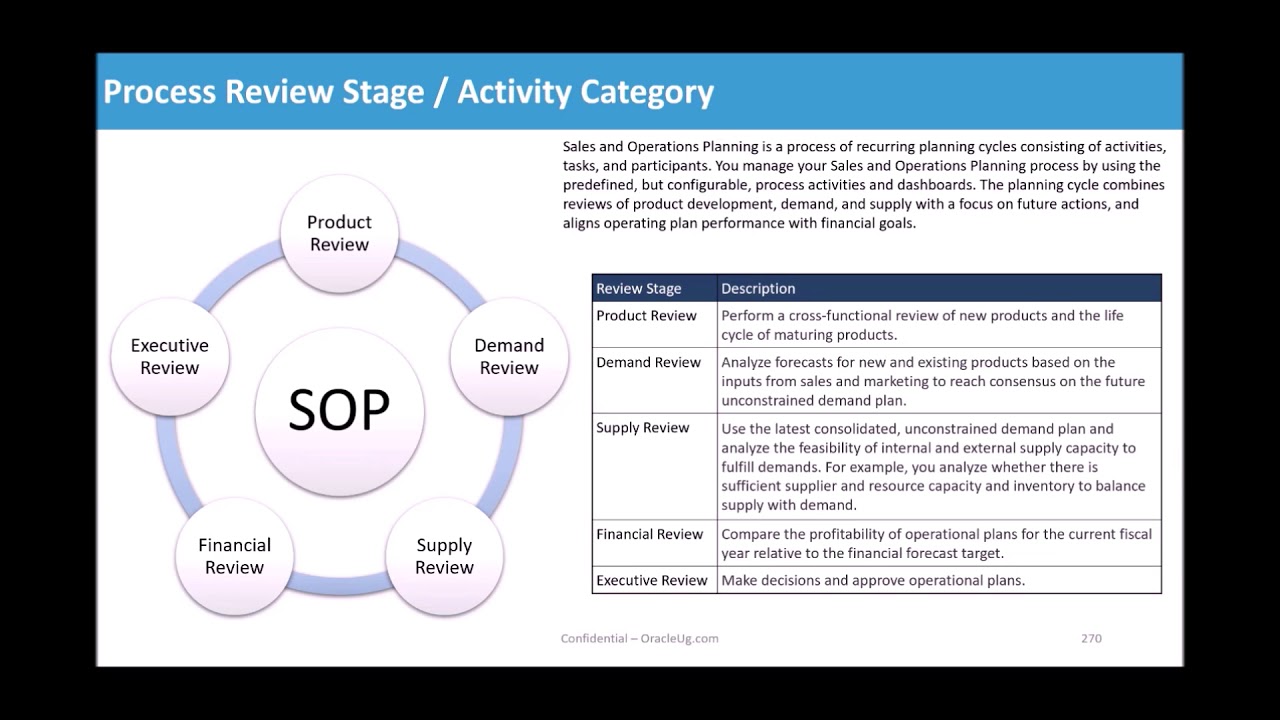

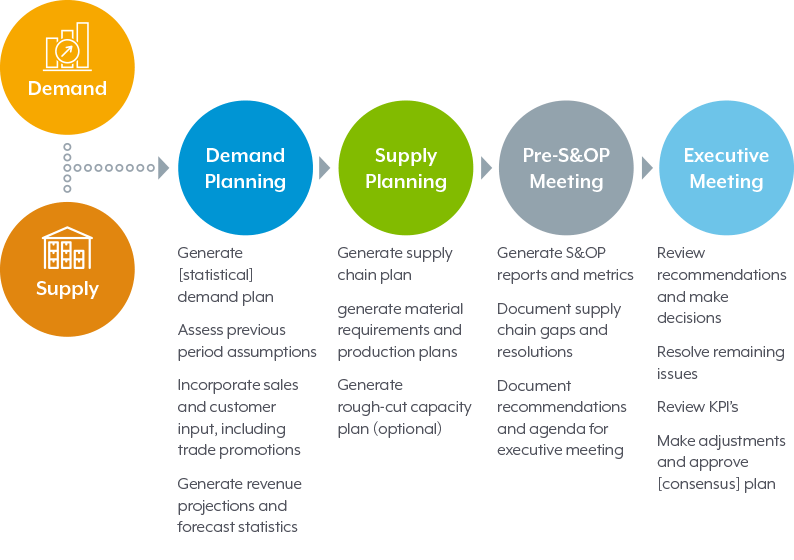

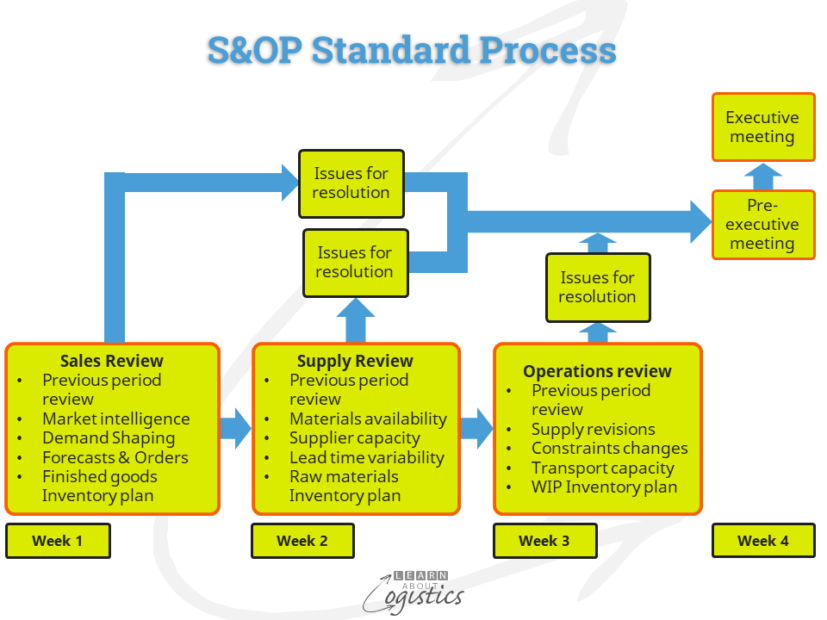

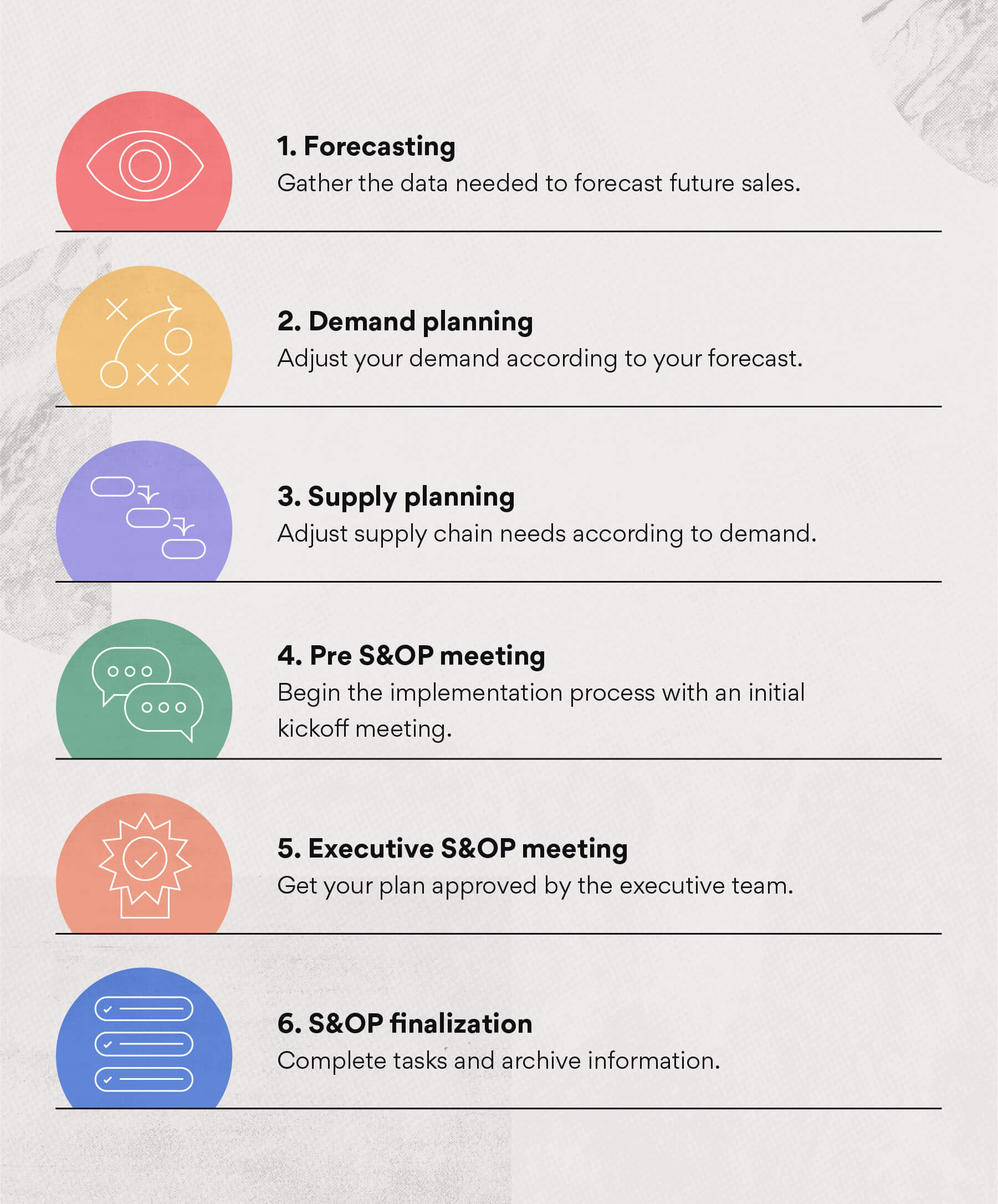

To deploy a performance management process Business drivers The S&OP Process The IBM Cognos S&OP Performance Blueprint helps manufacturers drive their S&OP process, identify changes in customer demand and supply plans, and simulate the impact of demand, supply, inventory and operating cost performance on financial statements Benefits to Adding Inventory Optimization to S&OP S&OP uses broad data from highlevel sources to develop demand forecasts that are then reconciled with the supply plan And it does so at the executive level in order to develop a cohesive and balanced business strategy Common Steps in the S&OP Process The S&OP process can be broken down into six essential steps data gathering and forecasting, demand planning, production planning, preSOP meeting, executive S&OP meeting, and the S&OP strategy implementation Let's take a look at each of these steps in greater detail 1

Sales And Operations Planning Supply Chain Business Solutions

What Is Sales And Operations Planning S Op Plex Demandcaster

To Make S&OP a reality in your organization, attend IBF's Virtual S&OP/IBP Boot Camp (with 1day Supply Planning Workshop) on February 22, 24 and 26 You'll learn from renowned leaders how to establish or improve your S&OP process and truly integrate demand and supply and improve key KPIs like cash flow, revenue, forecast accuracy, inventory turns, and moreSales and Operations Planning (S&OP) Process thrives on collaboration & honest communication between key organizational players Our process design approach is driven by the understanding of key touch points in the organization and how effective demand and supply communication among these touch points can be improved The S&OP process consists of five steps 1) Forecast Deliverable Statistic forecast 2) Demand Plan Deliverable Demand plan agreed upon with Sales, Marketing and, in some cases, with endcustomers

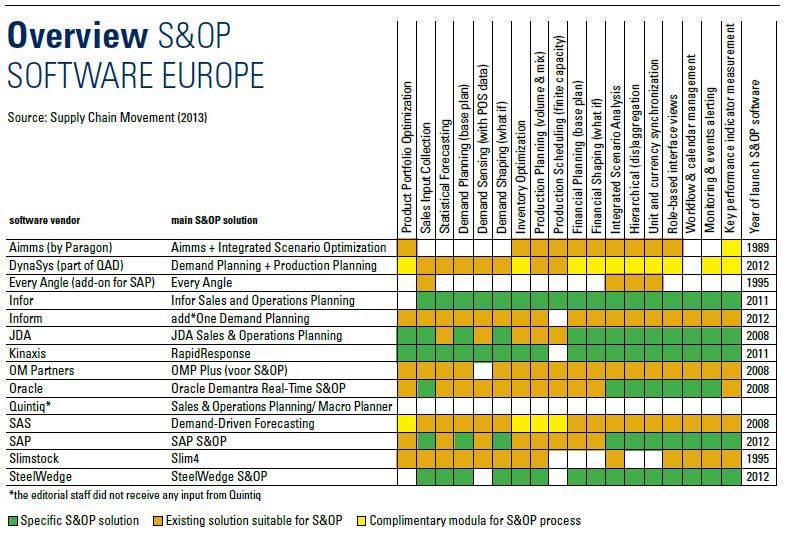

Software For Sales Operations Planning In Europe Supply Chain Movement

26 Ways To Get Sales On Board With Demand Planning June 13 16 Cscmp S Supply Chain Quarterly

Orthex moved towards a more robust planning process and got happy plannersThe APICS Dictionary, 15th edition, defines sales and operations planning (S&OP) A process to develop tactical plans that provide management the ability to strategically direct

S Op A New Frontier For Supply Chain Resilience 05 14 Cscmp S Supply Chain Quarterly

Sap Ibp S Op 2 Consensus Demand Scm Connections Tutorial Youtube

26 Ways To Get Sales On Board With Demand Planning June 13 16 Cscmp S Supply Chain Quarterly

Implement The S Op Process For Supply Chain Success Learn About Logistics

Sales And Operations Planning

Sales Operations Planning Why Is S Op Important

Scm Awareness S Op Process Planpotential

Supply Planning Processes Options Analytics Oh My Plex Demandcaster

Smoother Execution Through S Op Logistics Management

A Comprehensive Overview Of Sales And Operations Planning S Op

What Is S Op How S Op Works Demand Planning Com

Oracle Cloud Applications Supply Chain Planning Intro To Sales And Operations Planning Youtube

Demand Planner Terranova Strategic Hr Partners

Sales And Operations Planning Relex Solutions

Sales Role In Sales And Operation Planning Demand Planning The Sales Process Blog

Sales Operational Planning S Op Versus Integrated Business Planning Ibp Supply Chain Link Blog Arkieva

1

Supply Chain News What We See In S Op

10 Best S Op Software 21 Download Free Right Now Gmdh

What Is S Op Sales And Operations Planning Explained Anaplan

Pdf Sales And Operations Planning S Op An Overview

What S Holding The S Op Process Back Part Two Establishing A Business Efficiency Planning Process That Works Chainalytics

1

S Op Myths Part 5 Lean And On Demand Manufacturing Supply Chain 24 7

Fixing An Overly Complicated Sales And Operational Planning Process Supply And Demand Chain Executive

Optimise Your Sales And Operations Planning S Op Slimstock Uk

Sales And Operations Planning Process Self Assessment

Sap Integrated Business Planning Ibp Sales And Operations Planning 18 Sap Blogs

Sales Operations Planning Cirrus Supply Chain

A Paradigm Lost It S Not All About Changes In Demand

S Op Effectiveness Recommendations To Make The Leap Supply Chain Shaman

Dp Vs S Op Process Flow

Managing Risk In Your S Op Integrated Business Planning Process Supply Chain 24 7 Paper

Is S Op Excellence Slip Slidin Away Supply Chain Shaman

Good Sales And Operations Planning Is No Longer Good Enough Bain Company

The Differences Between Demand Planning Forecasting And S Op Demand Planning

Pdf Sales And Operations Planning Part I The Process Semantic Scholar

Ultimate Guide To Sales And Operations Planning S Op In 21

Demand Planning Process Key S Op Process Steps Involved In Forecasting Components In A Supply Chain

S Op In Las Vegas Let S Learn Laugh And Be Entertained At The S Op Innovation Summit

The S Op And The 3 Different Levels Of General Planning Based On Apics Download Scientific Diagram

A Common S Op Process For Your Business Helps Planning Learn About Logistics

A Comprehensive Overview Of Sales And Operations Planning S Op

Sales And Operations Planning Relex Solutions

Sales Operations Planning S Op Sap Library Sales Operations Planning S Op

Oracle Demantra Sales And Operations Planning User Guide

What Is S Op How S Op Works Demand Planning Com

Involving Execution Managers With Sales And Operations Planning Supply Chain 24 7

S Op Process

Sales And Operations Planning Business Forecasting Taruna Nagpal

Sales Role In Sales And Operation Planning Demand Planning The Sales Process Blog

Sales And Operations Planning A Project Manager S Guide Asana

Achieve Excellence In Sales And Operations Planning Sapinsider

3 Primary Components Of Sales Operations Planning People Process And Technology Supply Chain 24 7

Sales And Operations Planning

What Is S Op How S Op Works Demand Planning Com

S Op Heuristics Flow Chart Download Scientific Diagram

Sales Operations Planning Engagement Model Tvo Maine Pointe

S Op Made Practical The European Business Review

Implementing A Sales Operations Planning S Op Process Plex Demandcaster

How To Make The S Op Process More Robust Demand Planning

How S Op Improves Your Organization Tmc Fr

Sales And Operations Planning Report Do You Get Surprises

Integrating The S Op Process Go With The Flow Business 2 Community

5 Reasons Why Sales And Operations Planning Is Important Scmdojo

How Can Demand Management Drive Your Sales Operations Planning Moore

What Is S Op How S Op Works Demand Planning Com

How To Improve The Global S Op Process Demand Planning Com

S Op Is The Hub Of Supply Chains In Your Business Learn About Logistics

Mindmap For S Op And Ibp Supply Chain Movement

Demand And Supply Management In Uncertain Times

Sales And Operations Planning S Op 101 Smartsheet

1

Sales And Operations Planning S Op Logistiikan Maailma

Improving Profitability With Sales Operations Planning Magellan Consulting Group

Implementing A Sales Operations Planning S Op Process Plex Demandcaster

The 5 Most Common Sales Operations Planning Mistakes And How To Avoid Them Supply Chain 24 7

Sitmi Science Industrial Technology And Management Intelligence S Op Sales And Operations Planning Process Flow Simple And Quick Explanation Of Each Steps Facebook

Achieve Excellence In Sales And Operations Planning Sapinsider

S Op Implementation Roadmap

Getting To Grips With Sales And Operational Planning Bloor Research

The Sales And Operations Planning Process In The Context Of Various Download Scientific Diagram

Supply Chain Graphic Of The Week The S Op Process

The S Op Journey Beyond The Supply Demand Match Organization And Ownership For The Demand Planning Process Aberdeen Strategy Research

コメント

コメントを投稿